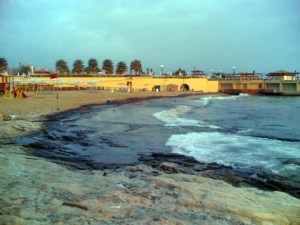

Oil Spill Equipment Glossary

Oil skimmer

Oil skimmers introduction

An oil skimmer functions by mechanically separating (skimming) oil floating on the surface of water, or skimming the top layer of fluid from a body of water.

The first type are called oloephilic as they use a process of adhesion to pick up the oil – eg a drum oil skimmer uses a rotating plate to which the oil adheres and is subsequently wiped off.

The second type are known as weir skimmers or suction heads. These devices reply on the oil flowing into a sump, trough or hopper or simply being drawn off the top.

It is important to know the following parameters before selecting an oil skimmer:

- Oil type

- Viscosity

- Temperature

- Drive (hydraulic / electric / pneumatic)

- Industrial or Marine (sea conditions)

- Transfer Pump configuration/type

- Static or Advancing

- Capacity

- Environmental conditions

The performance of oil skimmers can now be measured according to a new ASTM standard – F2709-08 www.astm.org

Oleophilic oil skimmer

Disc skimmers like all oloephilic skimmers are highly efficient and will only pick up a very small percentage of water. Equally once the oil has been recovered, if left to operate – will not recover water. Discs are constructed from PVC, aluminum or steel. The disc banks are driven by hydraulic motors, however electric and air motors are available in some models.

Brush skimmers are a relatively new concept, the rows of bristles can in the right conditions increase the amount of oil that can be recovered as it is trapped between the bristles. These devices can be configured for light or heavy oil. They can be for small units for inland spills or large offshore devices.

Drum skimmers are versatile skimmers that can recover a range of oils, from very light ( diesel / jet fuel ), to crude oils. Drum skimmers are driven by air or hydraulics. Air units may be considered for use in hazardous areas and can be hooked up the a vehicles air brakes for operation. They are typically lightweight, shallow draft and simple to mantain and operate.

Weir skimmers are manufacured in a range of materials which should be selected for the application. Stainless steel weir skimmers may be used in industrial tanks and ponds where chemicals and acids may be present.

The suction head is used with vacuum trucks and suction pumps. This head may be flat with openings on the perimeter, or a circular overflow device.

Open water weir skimmers are fitted with self-adjusting weirs – the ring surrounding the pump floats on the water level inside the hopper, when the hopper is pumped out the ring drops allowing surrounding oil to flow over the weir. These self-adjusting weirs are a great advancement over the early weir skimmer that relied on mechanical means to adjust the weir height / depth of skim.

Questions? Send us an email and we will be happy to help or refer you to one of our sponsors.

Click on pictures to enlarge.